BAAH-1: Intro to My L-1 Cert Project

It’s time: the bug’s bitten me. It’s time to work on a certification project so I can fly larger motors.

Why? No: this is not a case of, “Why not?” nor a case of, “Because it’s there.” I have a Vostok 1 model that I want to build. Lots of detail, complicated, a great project—that flies on H motors. That was—is—a problem: if I build it, I won’t be able to fly it. Though I toyed with the idea of using that as my L-1 cert bird, it didn’t take me long to stop toying.

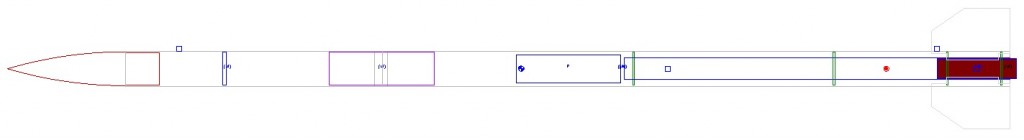

BAAH-1 will, though, be based on an historical rocket. In fact, it will be a full-scale model of that rocket: nearly 2 meters (a little over 6′) tall, 6.8 cm (almost 2¾”) in diameter, about BT-80 size. Not a big rocket: my Saturn 5 is much bigger in diameter, and Bedknobs and a Broomstick was just about this same size (built on BT-80, in fact).

I’m planning to over-design this rocket, in order to allow it to handle not just H and I motors, but to perhaps use it for my L-2 cert project, too, if the time comes I ever decide to venture into J and larger motors. Besides using thicker-walled tubes, more appropriate to high-power rockets than the Estes-compatible components—I’ll probably use Blue Tubes from Always Ready Rocketry—I’ll upgrade to aircraft plywood fins, bulkheads, and centering rings, U-bolts, a Fruity Chutes recovery system, and an Aero Pack motor retainer. I’m also going to include an avionics bay and dual-deployment capability, though the certification flight will almost certainly be single-deployment.

It doesn’t take a very astute eye to notice that the static stability margin is large: in fact, larger than I would like. That’s one of the challenges with this model: the original, like this, is very long, with comparatively large fins. I am considering adding aft ballast to bring the CG back along the rocket, but that will result in other problems, such as needing a motor with more thrust and, therefore, acceleration to ensure BAAH-1 reaches a safe speed before leaving the launch guide. Most likely, I’ll leave it as-is.

Currently, a friend, who has agreed to serve as my project mentor, is reviewing the plans. Once that’s complete, I’ll start buying parts and build.